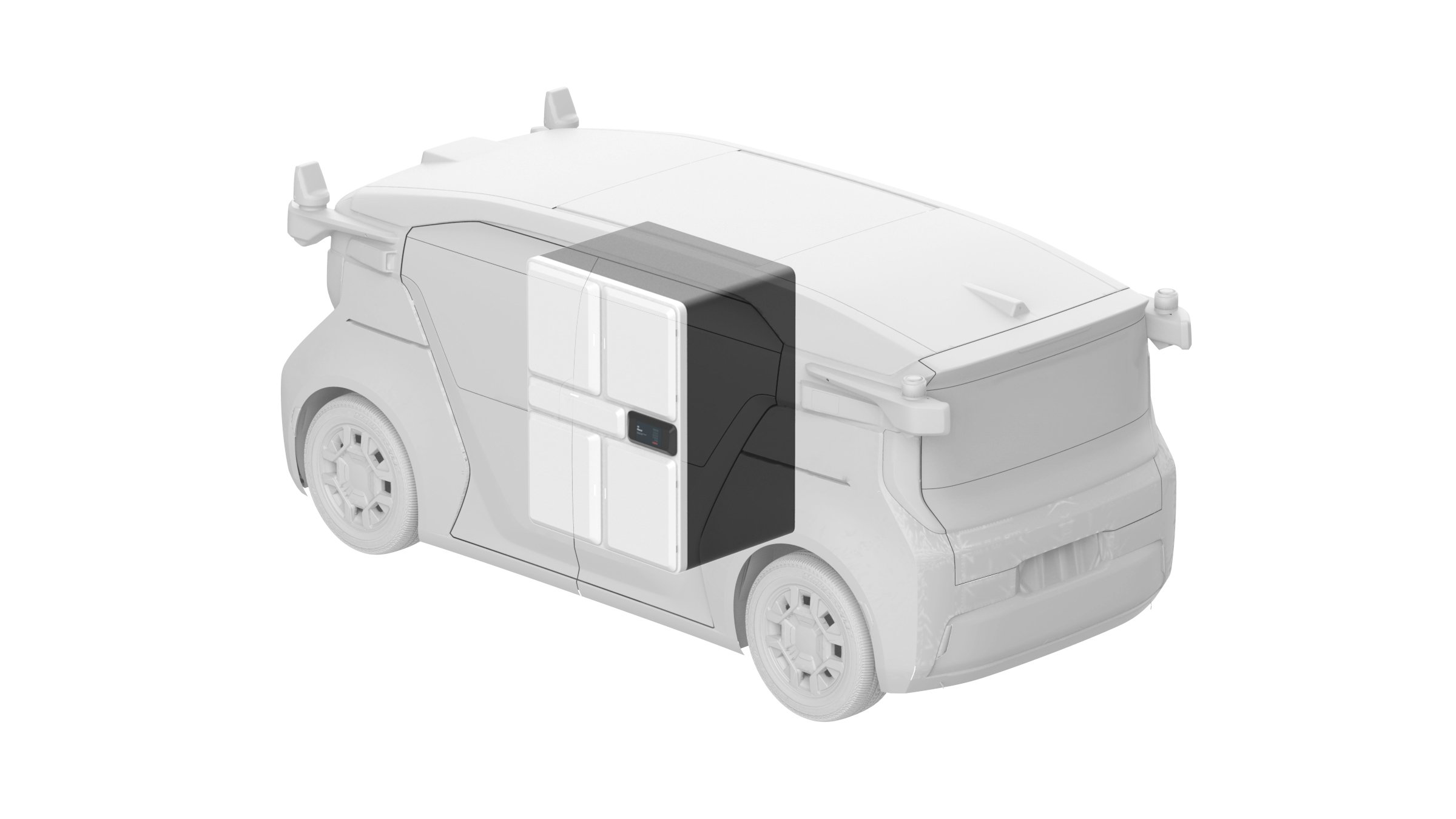

ORIGIN DELIVERY PLATFORM

Autonomous Delivery

Role: Lead Industrial Designer

Timeline: Started project Jun 2021 // Launching 2024

Team: 2 Industrial Designers, 1 Design Manager, 1 Product Manager, 4 Mechanical Engineers

The Origin Delivery Platform brings autonomous delivery capabilities to Cruise’s purpose-built autonomous ridehail vehicle. It is designed to be rugged enough to withstand the shock and vibration of driving around the city, and versatile enough to deliver prepared food, groceries, and packages. It is installed in the Origin on the floor space between the inward-facing passenger seats, and can be easily uninstalled to make the vehicle ridehail-ready. The team even designed and built a purpose-built robotic forklift to facilitate loading and unloading the locker unit.

The locker unit features 4 individually locking compartments and 1 dedicated pizza compartment, allowing it to hold up to 5 separate orders at a time. It has a customer-facing display which greets and instructs the customer. At the point of delivery, the customer meets the car at the curb, presents a QR code in the Cruise app, and the correct locker automatically lights up and pops open. Each locker compartment is sized to securely store a large order of groceries (up to 8 cubic feet), and oddly shaped items can also be stored in the vehicle’s trunk space.

The unit is built on an aluminum chassis, with a large EPP (polypropylene foam) insert which helps the structure absorb impact and vibration. The facade is powder coated stamped aluminum, and the inside of each cubby is hygienic thermoformed plastic in Cruise orange. Making the interior a bright color creates a moment of delight when the locker door opens, and helps with visibility of the contents. Each compartment also has a shelf which can bisect the space, or be stowed on the bottom for carrying large objects. The lower compartments are fitted with automated drawers to improve the customer’s unloading ergonomics.

The team ran several rounds of user testing to asses usability, ergonomics, and accessibility of the delivery platform. The ID and prototype engineering teams created a plywood locker prototype with functioning electronics to enable testing. Several aspects of the experience were tested and refined, including the UI, door unlocking procedure, and compartment size. The team also had the opportunity to fly to Walmart HQ in Bentonville, AR (during a historic ice storm) to present and test the unit with the Walmart team.